Efficient processing of lightweight materials using thermoplastic tapes.

Our production machines enable the manufacture of load- and waste-optimized semi-finished products and components.

Machine systems for the production of thermoplastic laminates with in-situ consolidation, thermoset laminates and dry fiber preforms

The increasing industrial use of fiber-reinforced plastics (FRP) worldwide requires automated FRP production technologies with unidirectional (UD) thermoplastic tapes, dry fiber rovings and thermoset prepregs to enable cost-effective lightweight parts with local UD fiber reinforcements. Conbility develops and supplies industrial machine systems for depositing and winding UD fibers (tapes, dry fiber rovings, thermoset prepregs), based on more than 25 years of experience of the Fraunhofer Institute IPT, Aachen, Germany.

Our machines and equipment

2D Thermoplast Tape Laying Machine

With our in-situ consolidation process, we achieve fully consolidated 2D laminates when processing thermoplastic tapes, thus replacing expensive (cost-intensive and energy-consuming) subsequent consolidation processes using appropriate presses.

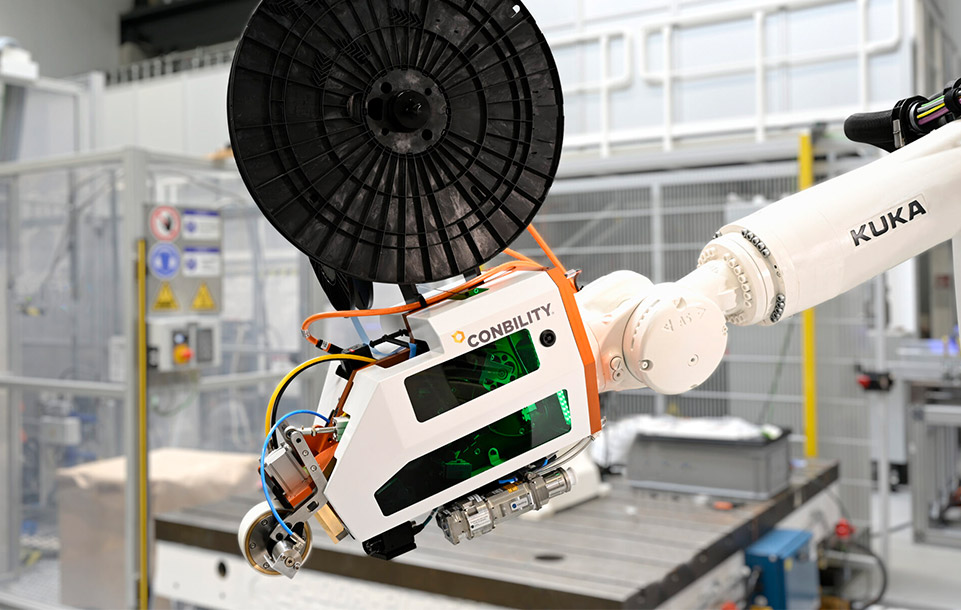

3D Multi Material Applicator

Our modular and multifunctional applicator for processing thermoplastic tapes, thermoset prepregs/towpregs and dry fiber can be integrated into existing robot systems and is equipped with decentralized control and HMI.

Our production machines are based on more than 25 years of experience in the field of laser-assisted tape laying. Conbility continuously cooperates with the Fraunhofer Institute for Production Technology (IPT) on the campus of RWTH Aachen University to implement and further develop our products. The use of lasers as a heat source for melting thermoplastic tapes is the best method for the rapid and temperature-controlled production of laminates for subsequent forming and direct component manufacture.

The temperature in the process zone is measured online and the laser power is controlled according to the should temperature. The high power density of the laser ensures high deposition speeds of up to 1 m/s while maintaining the quality of the tape.